Longevity:

Longevity:

Heat exchangers are manufactured only from corrosion resistant materials, the lamellae are of a high quality aluminum alloy.

Other manufacturers usually use galvanized steel for this, so the damage the punched pipe penetrations the zinc layer. At these locations,

is where the corrosion and in good time in the course of a few years tiny holes in the copper tubes. Due to this leakage, the gaseous refrigerant escapes,

S.D. costly repairs are needed and heat exchangers must be replaced.

Clarity:

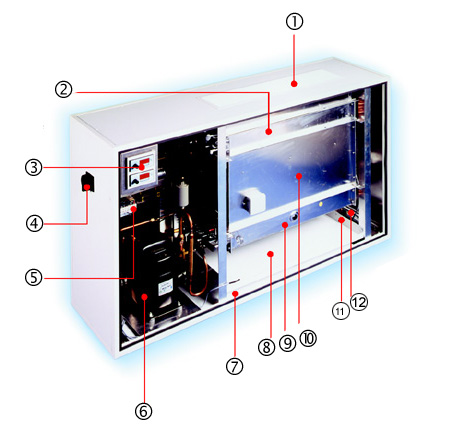

The device design is clearly structured, the controller easily accessible and service-friendly. The Unit design is clearly structured, the controller easily accessible and easy to service.

Heat exchanger tubes:

Heat exchanger tubes:

We use copper pipes with a minimum wall thickness of 0.8 mm, can withstand the swimming pool chemicals for many years.

Other producers are often not to be able to use such copper pipes, because their suppliers on material-saving production (wall thickness 0.4 mm) specialize. Such material thicknesses hold of the chemical loads of pools for a limited time.

Blower:

We use high quality fan from German production. The bearings are waterproof and designed for a lifetime of 20 years

.

Electronic controllers for temperature, humidity and CO2 levels indicate the actual value via a three-digit LED display and precisely regulate the setpoint.

Other manufacturers use inexpensive and wear-prone mechanical regulators, which have already after a few months in some cases considerable deviations.

Instead of the set 60% rel. Humidity switch mechanical cost control sometimes made only at 50%. These differences are hardly noted for the plant operator,

but can significantly increase the operating time and consequently also the energy bill.

Perhaps therefore finds no operating hours counter in such cheap devices. In all MORGENSCHWEIS-swimming pool dehumidifiers default

Operating hour meter installed in order to be able to demonstrate functionality and service life.